SLEEVE

March 30, 2024

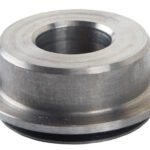

PROP THRUST WASHER

March 30, 2024

Description

- Function: The primary function of a washer is to distribute the load of a fastener over a larger surface area, thereby preventing damage to the surface of the connected parts, reducing friction, and ensuring a more secure and stable connection.

- Design: Washers are typically made of metal, plastic, or rubber and are available in various shapes, sizes, and thicknesses to suit different applications. They may be flat, countersunk, or have a raised center to accommodate the shape of the fastener or the surface it is being applied to.

- Types: There are several types of washers, including flat washers, spring washers, lock washers, and fender washers. Flat washers are the most common type and are used to evenly distribute the load of the fastener. Spring washers are designed to provide tension and prevent loosening of the fastener. Lock washers have teeth or serrations that bite into the surface to prevent rotation. Fender washers have a larger outside diameter and are used to distribute the load over a larger area, commonly used in automotive and construction applications.

- Applications: Washers are used in a wide range of applications across industries such as automotive, construction, manufacturing, and household appliances. They are commonly used in conjunction with bolts, screws, and nuts to provide additional support, reduce friction, and prevent damage to surfaces.

- Installation: Washers are installed by placing them between the head of the bolt or nut and the surface being fastened. They can also be used under the bolt or nut head to distribute the load evenly. The washer helps to prevent the fastener from digging into or damaging the surface of the connected parts.