ROLL PIN

March 11, 2024

TRIM TAB

March 11, 2024

Description

- Function: The screw secures the trim tab in place, allowing for precise adjustment of the tab’s angle relative to the water or airflow. This adjustment helps optimize the vehicle’s stability, performance, and handling characteristics, especially at varying speeds and conditions.

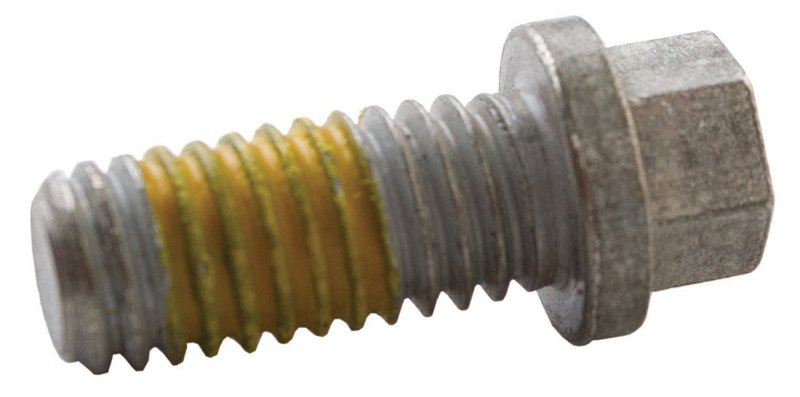

- Design: Typically, the screw has a threaded shaft with a head, which may be Phillips, flat, or hexagonal, allowing it to be tightened using a corresponding tool. The length and diameter of the screw are designed to fit precisely into the mounting holes on the trim tab and the vehicle’s surface.

- Material: Screws for trim tabs are usually made from corrosion-resistant materials such as stainless steel or aluminum, ensuring durability and longevity in harsh marine or aerospace environments. The choice of material depends on factors such as weight, strength, and compatibility with the vehicle’s construction materials.

- Installation: Installing the screw involves aligning the trim tab with the mounting holes on the vehicle’s surface, inserting the screw through the holes, and tightening it securely using the appropriate tool. Care must be taken to ensure proper alignment and tightness to maintain the desired trim angle.

- Adjustment: Once installed, the screw allows for easy adjustment of the trim tab’s angle by loosening or tightening it as needed. This adjustment may be performed manually or with the assistance of hydraulic or electric trim tab actuators, depending on the vehicle’s design and capabilities.

- Maintenance: Regular inspection of the screws and trim tab assembly is essential to ensure they remain securely fastened and that the trim tab operates smoothly. Any signs of loosening, corrosion, or damage should be addressed promptly to prevent malfunctioning of the trim system.